How does NotaZone work?

Follow the path of traceability to see how NotaZone will streamline your operation.

At NotaZone we are proud of developing a service for food producers that runs effectively from the first day and fits into your operations smoothly. We onboard many clients quickly and easily usually within a few weeks.

One key driver is to make recording all the information simple, so production staff are not encumbered by paperwork and record keeping and can focus on making great food!

Another is to provide all the features you need to run your business, but not force you to use them. NotaZone can fit into your ecosystem of business tools easily and at any level to provide the best solution for you.

Purchasing & Suppliers

NotaZone's purchasing module enables you to manage your suppliers and the products they supply to you, create and email purchase orders quickly.

Features include:

- Supplier list, groups and catalogues

- Ingredient cost management and reporting

- Conversion between UoM (Units of Measure)

- Simple customisable PO templates

- Print or email purchase orders

- Integrate with your finance system (Xero, QuickBooks, SAGE etc) to match supplier invoices

- Supplier approval

- Multi-currency purchase orders

Goods In

Simple Goods received recording with advanced features

Using Purchase Orders simplifies the Goods In process, minimising the input from staff. Advanced features allow for more involved requirements.

Feature include:

- Plan view of what is due to arrive

- Goods In register replaces your manual intake sheet

- Auto generated traceability batch/lot numbers

- Manual or Automatic selected storage location

- Print trace labels for all incoming materials

- Acceptance criteria for staff to check against

- Simple entry of quantity received in boxes, pallets etc with conversion to stock units (kg, litres etc)

- Quarantine unacceptable goods received

- Advanced forms enable you to add extra questions for different product types

Stock & Inventory

NotaZone's stock module manages your inventory in traceable batches

Feature include:

- Batch inventory management with product overview of stock on hand

- Stock level and expiry date warnings

- View batch level stock transactions

- Ad-hoc stock consumption recording (waste, NPD etc)

- Straightforward stock take process

- Batch location management

- 3PL module manages off site storage and fulfilment services

- Reporting of stock usage over time and stock valuation

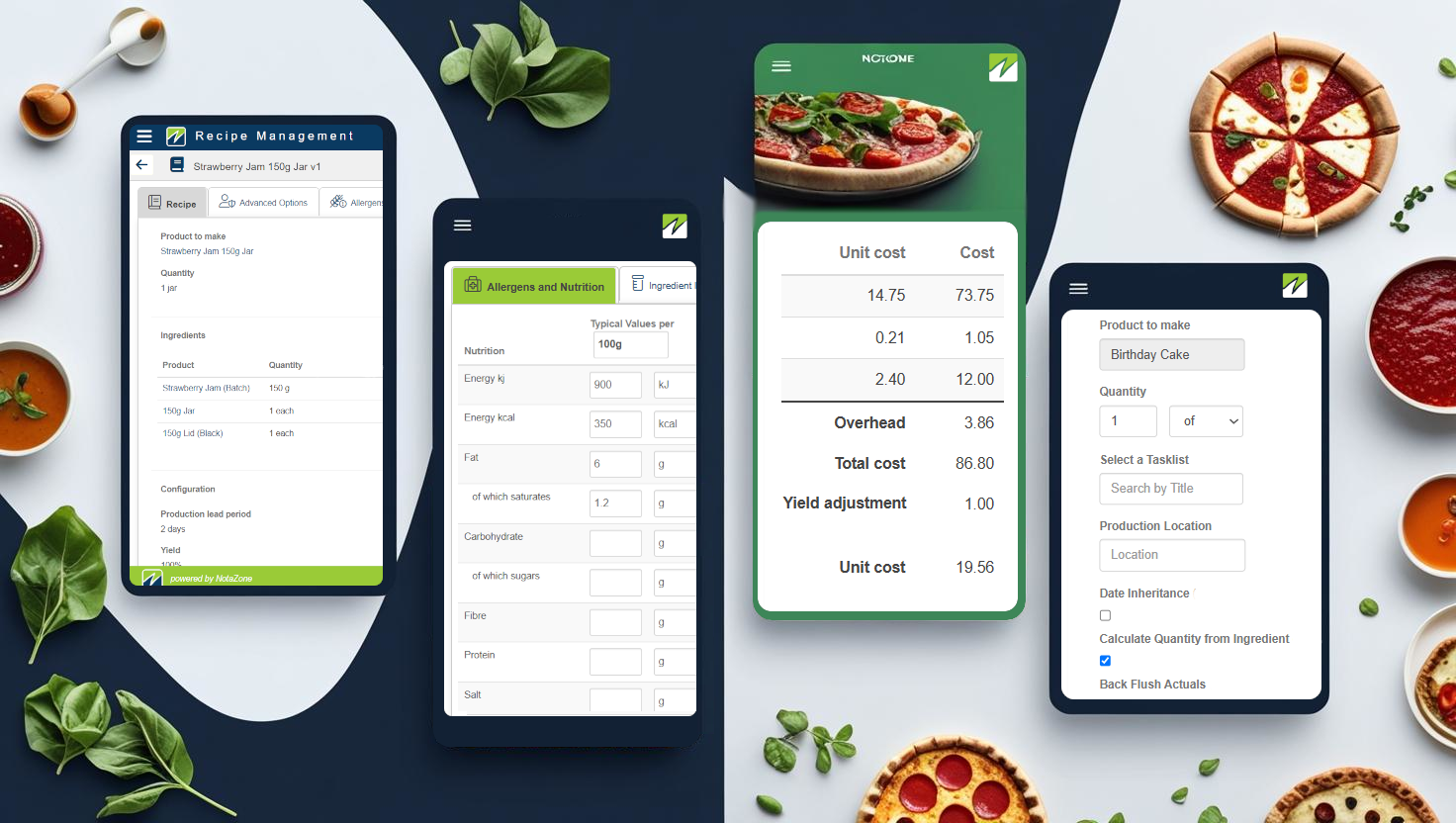

Recipes and BoM's

NotaZone's Recipe (or BoM) module simplifies management of how you make and package your products.

From food recipes through to BoMs for packaged products.

Feature include:

- Multiple recipes per product made for alternative ingredients or different processes

- Version control of recipes to manage change over time

- Calculation of UB/BB dates from the manufacture date

- Date inheritance between recipes for packaging level BoMs

- Calculate the cost of a recipe per stocking unit

- Backflush of actuals through a chain of recipes

- Batch production scaling

- By-Products, records additional products created from your process

- Cyclic recipes (e.g. starter from one batch to another)

Planning & Forecasting

Simple tools to provide advance features.

NotaZone will use the information you provide on future and past production and sales to assist your with your production planning process.

Features include:

- Product forecasting

- Demand Planning

- Plan using manual or forecast demand numbers

- View raw materials requirements

- Generate production orders for the entire plan

- Link through to generate purchase orders

- Raw material prediction

- Seven day and seven forward view of stock over time

- Planning data can be fed from other systems

Production

NotaZone's Production module keeps your production records in one place and replaces paper based recording.

Features include:

- Production orders are created from recipes to schedule production

- Plan view of what is scheduled to be made

- Daily pick lists to show all materials needed for the day

- "Scan and pick" technology to record the materials used

- Set actual quantities when production is complete to record what you made

- CCP and Metric recording through tasks lists

- Report the actual cost of every batch made

- Report ingredient usage over time

Compliance & Traceability

NotaZone's compliance module is the heart of the system keeping all your records in one place and quickly available when you need them.

Feature include:

- Tasks lists to capture CCPs and other metrics.

- Recipe task lists for production batches

- Daily Weekly and Monthly recurring for general recording

- Despatch task lists attached to sales orders

- Ad-hoc task lists for anything else

- Supplier to Customer full traceability

- Recall data available quickly from any level or batch

- Allergen management & Nutritional data through products and recipes

- Reporting of CCPs and metrics over time

- Fully compliant with the requirements of SALSA, BRCGS, Red Tractor, Soil Association and more.

Labelling

NotaZone's labelling module enable you to build rich labels for your products, cases or shipments

Features include:

- Compliant with regulatory requirements for food labelling

- Compatibility with GS1 standards and RFID labelling

- Works with most common label printers (Zebra, TSC, Brother, etc)

- Template based label generation supports any label size

- Include names, batch details UB/BB dates, ingredients, allergens and nutritional data and more.

- Use any type of barcode to your labels (1D and 2D) and add multiple barcodes

- Non-standard custom barcodes can be created

Sales orders

NotaZone Sale module manages sales and customers efficiently

Feature include:

- Customer management (CRM) with tiered price lists and customer groups

- Customer notes available when viewing orders and at despatch

- Multi-currency supported

- Integrations with many eCommerce platforms and through EDI

- Customer web portal with order cut-off dates and delivery routes

- Sales formats (sell in boxes , stock in singles)

- Email confirmation of sales orders

- Standing orders

- Follow on orders for short shipping

- Customisable confirmation, picklists and deliver notes (set per customer, or group)

- Integration with Optimo and PodFather for route planning and delivery

- Reporting of sales over time by customer and product

- Reporting of profitability of sales order

- Returns of goods from customers

Despatch

NotaZone's simple despatch process record the batches sent to every customer

Feature include:

- Plan view of what is due to leave

- Pick list show everything you need to send 'today'

- "Scan and pick" with mobile devices for simple recording of what is sent to each customer

- Task lists available to record CCPs and metrics at despatch

- Customised despatch notes for printing or emailing

- Automated printing and emailing of despatch notes

- SSCC label generation for palletised or packed goods

- EDI ASNs creates and transmitted

Invoicing

NotaZone passes despatch order to your finance system to auto-generate customer invoices

- Integrates with all major finance systems

- Removes rekeying of order information for invoicing

- Create invoices based on what was picked, not what was orders

- Passes pricing across to avoid errors

- Web links to finance system for cross-referencing

Mobile apps

NotaZone's mobile apps make staff lives easier by providing task focused activities

Features include:

- Multiple users per device

- Wireless scanners for barcode capture

- Focused operations for simple workflow

- Icon based layouts for multi-lingual users

- Fast, simple data entry for production staff

Additional Modules *

NPD - New Product Development

- Create project to manage product development

- Create multiple recipe ideas with a project

- Add new NPD materials or use existing

- Create test production orders

- View the cost of each recipe version

- Test and Record by adding 'questions' to a project

- Score recipe versions against all or some of the questions

- Take the final version through to live

- Ring fence all NPD Products and Recipes from normal production and planning views

RFID

Features include:

- Use RFID technology to track inventory

- Produce RFID programmed labels for stock units

- Use RFID gateways to record movement

- Streamline despatch recording with RFID

- Compatible with all major RFID equipment manufacturers

Large screen displays

Features include:

- Show KPIs or Production/Despatch schedules to live for staff

- Keep staff up to date with changes to plans

- Show live progress of production workflow throughout the day

* Additional modules are available on Standard and Premium plans only